Nutritious Baby Rice Powder Instant Cereal Baby Food Production Line

Basic Info

| Model NO. | SLG65/70/85 |

| Certification | CE, ISO9001, SGS |

| Power Source | Electric |

| Process | Baby Food Cereals |

| Automatic Grade | Automatic |

| Application | Popcorn, Chips, Baby Food Cereals |

| Customized | Customized |

| Machinery | Nutritional Powder Baby Food Machine |

| Machine | Snack Food Machine |

| Transport Package | Wooden Case |

| Specification | CE, ISO, SGS |

| Trademark | Jinan Dayi |

| Origin | Jinan |

| HS Code | 84198100 |

| Production Capacity | 3000PCS/Year |

Product Description

Nutritional powder baby food cereals snacks making machinery

Description

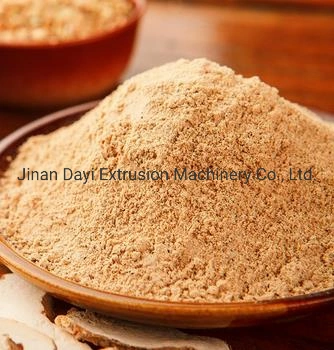

Nutritional powder baby food processing line

Brief decription:

This Nutritional powder baby food processing line takes place of the traditional stir-fry handiwork which is in low efficiency and usage of raw materials and less controal of sanitation and quality. This nutritional powder processing line uses screw extruding technique to cover those disadvantages. It not only can process garin materials, like buckwheat, oats, soybean powder, etc, but strengthen the nutrients to produce multi-fuctional healthy food for people especially for baby. Such powder food can provide various nutrions and is easy to eat by filling in hot water.

Production Flow:

Flour Mixer → Double-screw Extruder → Air Conveyor → Dryer → Grinder

Technical Parameters:

Model | SLG65-CJ | SLG70-A |

Installed power | 81.57kw | 110kw |

Power consumption | 53kw | 80kw |

Capacity | 100~150kg/h | 250-300kg/h |

Dimension | 16500×1150×2350mm | 19500×1150×2350mm |

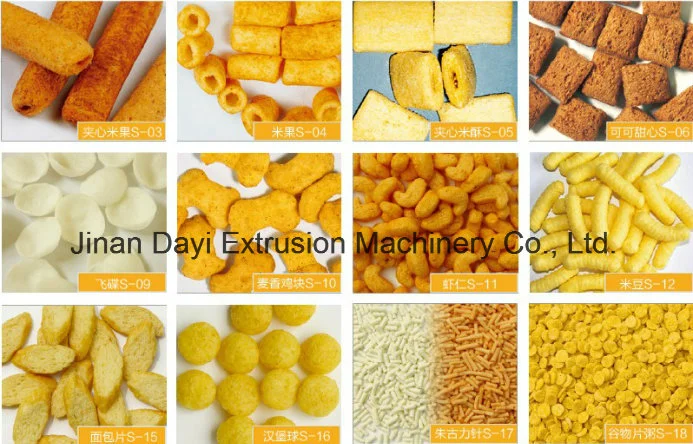

Snacks produced:

JINAN DAYI EXTRUSION MACHINERY CO.,LTD

Established in 1996, Jinan Dayi Extrusion Machinery has been the professional manufacturer and the model company for advanced and high efficient extrusion food machinery in this field. DAYI Company congregates an expert team with twenty-year experiences in this extrusion machine industry, not only working hard to constantly researching extrusion technology, but also exploring food processes in order to benefit our clients producing creative food.

After years of research and development, our single and double screw extrusion technique has been widely applied to produce the following products: puffed snacks, core-filling snacks, breakfast cereal / corn flakes, 2d/3d pellet, textured soya protein/fibre protein/vegetarian meat, doritos/ tortilla chips, cheetos/niknak/kurkure, ball/butterfly popcorn, fried flour food, bread crumb, nutritional rice/ artificial rice, nutritional powder/baby food powder, and pet food, etc. More than twenty production lines with different functions and capacities can be chosen. And we can also provide customized service for special requirements.

"Create Greatest Value for Clients" is our consistent concept and the base of long-term cooperation with clients. In these years, our machines have large domestic market share. Some food companies famous now grew up together with us, and many influential large food companies and groups have chosen us and set up long-term cooperation, such as, China Oishi Food Company (headquarters in Philippines), Panpan Food (Fuyuan Group), Hsufuchi Group, Fujian Qinqin Incorporated, Wangwang Group, Master Kong Company, Tianjin Longkang Company, Jiangsu VV Group, Fuwa Group, Gloden Monkey Food Company, Hebei Dingda Food Group, Hangzhou Daen company, etc.

Meanwhile, our machines have been exported to about fifty countries and regions for these twenty years, such as Malaysia, Indonesia, Philippines, Vietnam, Cambodia, Thailand, Japan, South Korea, India, Pakistan, Russia, Kazakhstan, Uzbekistan, Turkmenistan, Jordan, Iran, Israel, UAE, Egypt, South Africa, Algeria, Congo, Netherlands, Poland, Macedonia, Czech, Brazil, Argentina, Mexico, Australia, etc. Dayi machines have gained high reputation for the high quality, low cost, and low consumption. And we will continuously provide the best machines and best services.

If you have any need for our snacks machines, please contact us when feel free.Also welcome you come to have a visit of us.