India Nutritious Artificial Fortified Rice Kernel Extruder

Basic Info

| Model NO. | JY-65/70/85 |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Processing Type | Twin Screw Frk Rice Extruder |

| Capacity | 200kg/H, 250kg/H, 400kg/H, 500kg/H, etc |

| Shapes | Various Upon Clients′ Demands |

| Voltage | 380V/50Hz or Customized |

| Power | 60kw or Customized |

| Raw Material | Rice Flour and Broken Rice |

| Energy | Electricity, Diesel, Gas, Steam |

| Machine Material | Stainless Steel |

| Motor | Siemens, ABB or Chinese Brand |

| Electric Part | Siemens or Chinese Brand |

| After-Sales Service Provided | Field Installation, Commissioning and Training |

| Weight | 3-5t |

| Color | Silver |

| MOQ | 1set |

| Transport Package | Plastic Film as The Packing |

| Specification | Customized |

| Trademark | JOYANG |

| Origin | Shandong |

| HS Code | 8438800000 |

| Production Capacity | 40 Set/Sets Per Month |

Product Description

India Nutritious Artificial Fortified Rice Kernel ExtruderIntroduction

India Nutritious Artificial Fortified Rice Kernel Extruder is developed to meet the demands of food nutrition.This extruder is improved to avoid the loss of nutritional elements in the rice which is made by the traditional rice processing.It has characters of high automatic,easy operation, energy saving and environmental protection.The raw materials for artificial rice processing can be rice,black rice,buckwheat and other grains(broken rice and rice bran can be reused).You can also add additional nutrient components, such as vitamins, minerals etc.After extruding, forming and drying, you can get the nutritional artificial rice,which is eaten same as natural rice.

Machines List

Mixer--Screw conveyor-- Twin screw extruder-- Sifter-- Air conveyor--Dryer--Cooling conveyor

Technical Advantages

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

Raw materials

Broken rice, rice flour, other grain flour, vitamin premix, nutrition powder, etc.

Final Products

Artifice rice, fortified rice, nutrition rice, instant rice and so on.

Technical Parameter

| Model | JY-70 | JY-75 |

| Installed Power | 100kw | 144kw |

| Power Consumption | 60kw | 100kw |

| Capacity | 200kg/h | 200-350kg/h |

| Dimension | 18x2x3.5m | 21x2x3.5m |

Company Information

Shandong Joyang Machinery is a professional supplier of food processing machines. Our company's Motto is: "Service and quality are equally important". We offer to cooperate with our customers for mutual and beneficial development. All Inquiries are welcome.

We have through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill.

We are located in Jinan, the Capital of Shandong Province. We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the clients specific requirement, we also design and produce the machines to order.

Our main products line include puffed snacks production line, core filling snack production, corn flakes/ breakfast cereals production line, pasta / pellet chips production line, kurkure production line, artificial rice production line, pet food production line, etc Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

Whatever food processing machine you need from China, contact: Shandong Joyang Machinery Co; Ltd. A one stop shop in the middle of China.

Our Service

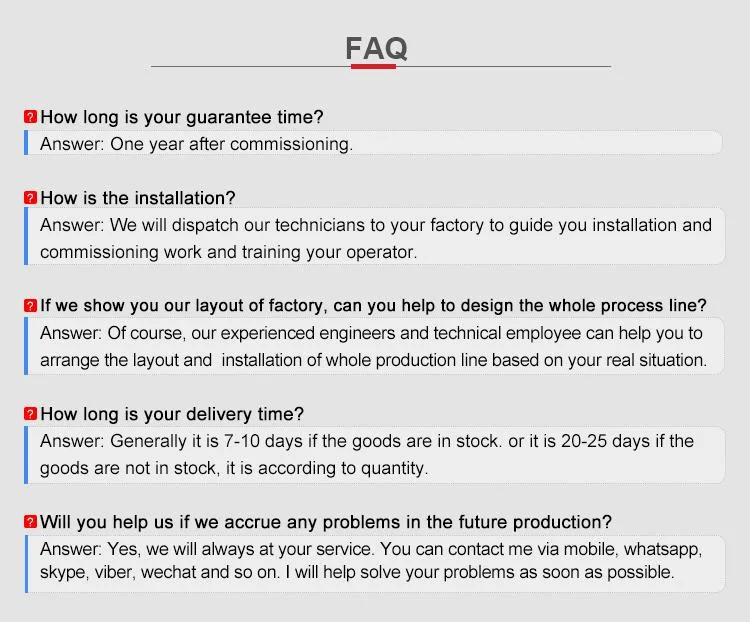

We will provide the most thoughtful services for our clients:Before sales service of the extrusion machine1.Free consultation service before, during, and after sales;2. Free Project planning and design services upon clients' special demands;3. Debugging and inspecting of equipment until everything is functional before leaving the factory;During sales service of the extrusion machineManagement of equipments' long distance shipping from seller's factory to the named place by buyer;After sales service of the extrusion machine1. Training of equipment maintenance and operating personally;2. New production techniques and formulas;3. Provide 1 year complete warranty and life-time maintenance service.Packaging & Shipping

Packing: inside plastic bag, outside wooden case(Based on the customers' need adopt the wooden case or wooden pellets, etc.).

Delivery Details : 30 days after order